Special Reports

2016 Quarter 2 Issue 27

Make Your Imagination Thousands of Surprises

——— News Express of Chinaplas2016

As global second largest rubber and plastics exhibition, CHINAPLAS has gathered world-class plastic technologies offering multiple premium solutions for enterprise upgrade and transformation. The CHINAPLAS 2016 will be held in Shanghai New International Expo Center (Pudong) during April 25th~28th. Over 3,200 exhibitors and groups from different countries would participate in this prestigious meeting. Acting as world leader in the field of auxiliary equipment, SHINI will display its latest product and innovative technology, demonstrate full completed production line of molding auxiliary equipment in the show to present our innovation ideas and whole system solutions by this opportunity.

Global manufacture based countries have drawn up corresponding national strategy to adapt transformation in new era and upgrade its industrial competitiveness. For example, the Germany “Industry 4.0”, America “Industrial Internet”, and Japan “Robots New Strategy” etc. While China’s proposal “Made in China 2025” activates China’s manufacturing development all round with great changes. However, they all focus on the same essential point that is the intelligent manufacturing: the production, equipment and product intellectualization. It is estimated that intelligent manufacturing will be involving in various fields, including the rubber and plastics industry. Same as other field’s manufacturing in China, the rubber and plastics industry is getting into the new age of intelligent manufacturing with upgrade and transformation.

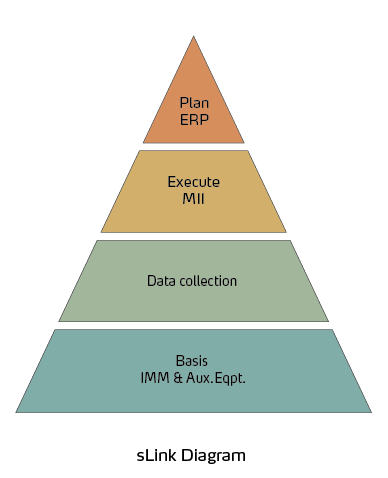

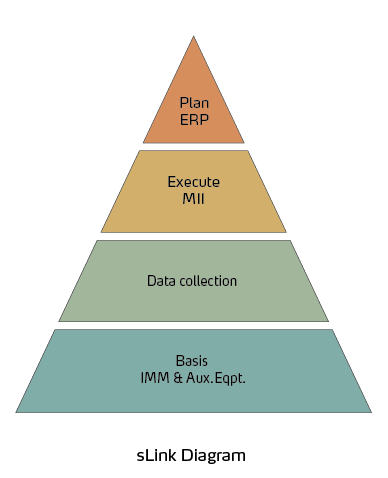

Surfing in intellectualization waves, Shini acts like a brave surfer who holding the leadership in the field, launched the integration technology sLink based on network control years ago. Through the network, it achieves central monitoring of all molding auxiliary equipments. This technology won a great deal of recognition and appreciation when it first introduced in Chinaplas2014. However, there’s only a few manufactures noticed the important of intelligent manufacturing. Most of the customers just take a glance for the show that didn’t take actions to change their production mode. Burdened with high costs and low profits, it is getting harder and harder for traditional enterprise, while taking the intelligent technology becomes a great power for enterprise to make progress in the recession. Adapting to this trend, the new type of production and facility is widely adopted in the industry, and sLink technology gains more and more clients with their approvals. In this exhibition, numerous famous manufacturers as HAITIAN, CML, BORCH, YIZUMI would bond with SHINI equipments as well as sLink technology to achieve intelligent injection molding. Moreover, we are taking deeper efforts in research over current sLink technology to display the whole system with intelligent solutions that time, including control technology integration, systems of MES and ERP, you can experience the convenience of intellectualization.

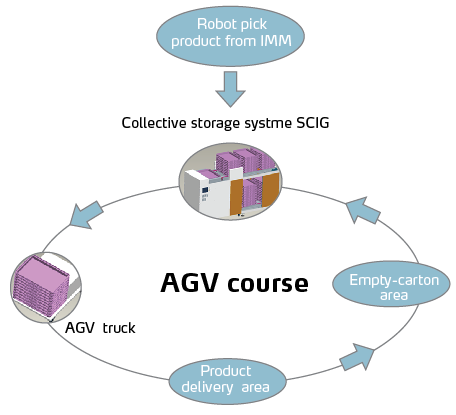

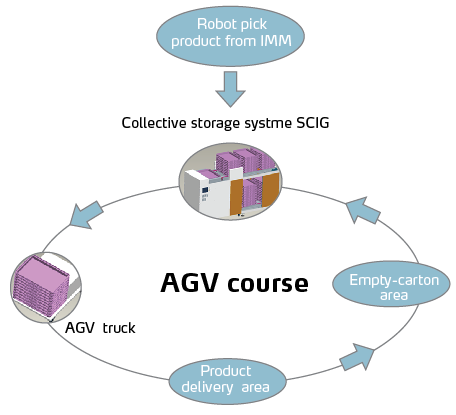

Automation solution is absolutely important in future intelligent plant. We will display the SCIG (collective storage system) and AGV (automated guided vehicle) with the solution in this show. The process is that after products are packed in cartons, they will be collected in the system; The AGV vehicle will transport all these cartons to product delivery area. After delivery, the vehicle will move to pick other cartons for next storage, and then transport the cartons to product delivery area again with full-load system to repeat the circulation. The SCIG system is applicable to pile up, collect products and for the conveying. Multiple cartons are packed in empty-carton area on SCIG system, while single carton will be conveyed to product-stacking area. After products are picked out from the injection molding machine and piled up in the cartons by Robot, the up-down server will stack the full-load cartons, and then transport other empty cartons to product stacking area for the circulation. Afterward, the cartons will be conveyed to delivery section of SCIG system and wait for the AGV vehicle. The AGV also named as unmanned transport truck, it is an automated guided vehicle, which can complete the appointed tasks according to preset course and program。 For modern intelligent plant, AGV not only features reduced operator but also could withstand the heavy load.

Automation solution is absolutely important in future intelligent plant. We will display the SCIG (collective storage system) and AGV (automated guided vehicle) with the solution in this show. The process is that after products are packed in cartons, they will be collected in the system; The AGV vehicle will transport all these cartons to product delivery area. After delivery, the vehicle will move to pick other cartons for next storage, and then transport the cartons to product delivery area again with full-load system to repeat the circulation. The SCIG system is applicable to pile up, collect products and for the conveying. Multiple cartons are packed in empty-carton area on SCIG system, while single carton will be conveyed to product-stacking area. After products are picked out from the injection molding machine and piled up in the cartons by Robot, the up-down server will stack the full-load cartons, and then transport other empty cartons to product stacking area for the circulation. Afterward, the cartons will be conveyed to delivery section of SCIG system and wait for the AGV vehicle. The AGV also named as unmanned transport truck, it is an automated guided vehicle, which can complete the appointed tasks according to preset course and program。 For modern intelligent plant, AGV not only features reduced operator but also could withstand the heavy load.

The intellectualization not only lies in system solutions, but also involves in single unit which requires this technology as well. In this show, SHINI will exhibit the large scale of Smart Energy-saving Dehumidifying Dryers; its smart control system can adjust the airflow automatically according to the air temperature exhausted by the hopper, which saves energy in avoidance of material over-drying. Besides, the heat regenerative recycler vastly lowers the power consumption and reduces the costs. The new designed drying hopper with decent proportion ensures consistent drying time of all the materials for optimal drying effect.

The intellectualization not only lies in system solutions, but also involves in single unit which requires this technology as well. In this show, SHINI will exhibit the large scale of Smart Energy-saving Dehumidifying Dryers; its smart control system can adjust the airflow automatically according to the air temperature exhausted by the hopper, which saves energy in avoidance of material over-drying. Besides, the heat regenerative recycler vastly lowers the power consumption and reduces the costs. The new designed drying hopper with decent proportion ensures consistent drying time of all the materials for optimal drying effect.

At the same time, we would exhibit the latest Air-cooled Water Chiller features high Coefficient of Performance, which exceeding the 1 grade of the China standard, sufficiently takes the advantage of the energy. Meanwhile, its patent self-drive mixing tank effectively balances the water temperature inside. Combined with the optimized structure and production technology, it ensures the machine always works in reliable condition.

At the same time, we would exhibit the latest Air-cooled Water Chiller features high Coefficient of Performance, which exceeding the 1 grade of the China standard, sufficiently takes the advantage of the energy. Meanwhile, its patent self-drive mixing tank effectively balances the water temperature inside. Combined with the optimized structure and production technology, it ensures the machine always works in reliable condition.

As global second largest rubber and plastics exhibition, CHINAPLAS has gathered world-class plastic technologies offering multiple premium solutions for enterprise upgrade and transformation. The CHINAPLAS 2016 will be held in Shanghai New International Expo Center (Pudong) during April 25th~28th. Over 3,200 exhibitors and groups from different countries would participate in this prestigious meeting. Acting as world leader in the field of auxiliary equipment, SHINI will display its latest product and innovative technology, demonstrate full completed production line of molding auxiliary equipment in the show to present our innovation ideas and whole system solutions by this opportunity.

Global manufacture based countries have drawn up corresponding national strategy to adapt transformation in new era and upgrade its industrial competitiveness. For example, the Germany “Industry 4.0”, America “Industrial Internet”, and Japan “Robots New Strategy” etc. While China’s proposal “Made in China 2025” activates China’s manufacturing development all round with great changes. However, they all focus on the same essential point that is the intelligent manufacturing: the production, equipment and product intellectualization. It is estimated that intelligent manufacturing will be involving in various fields, including the rubber and plastics industry. Same as other field’s manufacturing in China, the rubber and plastics industry is getting into the new age of intelligent manufacturing with upgrade and transformation.

Surfing in intellectualization waves, Shini acts like a brave surfer who holding the leadership in the field, launched the integration technology sLink based on network control years ago. Through the network, it achieves central monitoring of all molding auxiliary equipments. This technology won a great deal of recognition and appreciation when it first introduced in Chinaplas2014. However, there’s only a few manufactures noticed the important of intelligent manufacturing. Most of the customers just take a glance for the show that didn’t take actions to change their production mode. Burdened with high costs and low profits, it is getting harder and harder for traditional enterprise, while taking the intelligent technology becomes a great power for enterprise to make progress in the recession. Adapting to this trend, the new type of production and facility is widely adopted in the industry, and sLink technology gains more and more clients with their approvals. In this exhibition, numerous famous manufacturers as HAITIAN, CML, BORCH, YIZUMI would bond with SHINI equipments as well as sLink technology to achieve intelligent injection molding. Moreover, we are taking deeper efforts in research over current sLink technology to display the whole system with intelligent solutions that time, including control technology integration, systems of MES and ERP, you can experience the convenience of intellectualization.

Special Reports

- Review 2015 and Look Forward to 2016

- Model Selection and Notices of Cooling Tower

- Energy Saving Technology Applied in Water Chiller

- Rotary Valve

- "The Classroom" Debuted A Huge Success

If you want to read other articles, back to2016 Quarter 2 Issue 27.