Special Reports

2016 Quarter 2 Issue 27

Model Selection and Notices of Cooling Tower

When using the Water-cooled Water Chiller, for continuous reliable operation of the machine, it needs to adopt a suitable cooling tower to dissipate the heat. The model selection of cooling tower is according the refrigerant capacity to select the tower with matching heat-dissipation capacity. The main responsibility of cooling tower is to diffuse the heat reserved in cooling water to ambient environment for the purpose to cool down the inlet water temperature of the water chiller. The selection of cooling tower is just the selection of appropriate heat-dissipation capacity, which aims to satisfy the heat load of the water chiller. It cools down the condenser and prevents Water Chiller insufficient heat dissipation that would cause the risks of condenser overheat and high pressure abnormality.

In actual use, the cooler sometimes turns out lacking of enough heat-dissipation as the inappropriate heat-dissipation capacity of cooling tower adopted by Water Chiller, resulting abnormal operation of the machine. The risk of incorrect selection of cooling tower lies in when the Water Chiller load exceeds cooling tower heat-dissipation capacity, the water heat in tower can’t spread to ambient environment which makes cooling water temperature risen. It can’t meet the temperature requirement of inlet water, and can’t achieve condenser required rated heat exchange, synchronously the refrigerant system lasts high pressure high temperature as well. If things continue this way, the high temperature would melt the condenser components, taking refrigerant leaking method to release the pressure and reduce the temperature, it results Water Chiller suspension involving poor cooling effect of the injection molding machine which would cause dangerous safety risks, therefore the correct selection of cooling tower is crucial.

It’s forbidden to equip the water pool in cooling tower’s circulation system. As the added water pool, only can increase the amount of cooling water for water storage and buffer use, it has no heat exchange and temperature cooling functions. Moreover, as the large capacity of water pool, we don’t change the water usually. The concentration of calcium ion and silicon ion in the water pool slowly increases as use goes by. The refrigerant temperature at cooler inlet can reach 80~90℃/176℉~194℉, the water is boiling at this site, so it generates white hard incrustation like calcium carbonate and silica acid accumulated inside condenser copper pipe. The water scale is very tough insulation material which blocks heat conduction and largely affects the heat exchange of the cooler, resulting refrigerant heat can’t be taken away by the cooling water, and brings about high pressure of the Water Chiller. When this situation appears, it must use steel brush to remove the water scale on the copper pipe, or use acidic substance to melt the incrustation. As the same reason, if injection molding machine uses water pool to dissipate heat, the mould of injection molding machine is much higher than Water Chiller, the heat-dissipation tunnel inside mould will generate thicker hard scale, which results mould long last high temperature with longer de-mould cycle. The most effective method to avoid circulation water system scaling is to soften the water quality for scale cleaning. Change the circulation water once a week is available to lower the water scale possibility, and do clean the cooling tower regularly. The cooling of condenser, for Water-cooled Water Chiller, is completed by tower circulation, and the self-added water pool could turn out to be the poor effectiveness, with many troubles. Therefore, it only needs to consider the capacity of water tower in the circulation, the adding of water pool is forbidden.

In cooling water pipe engineering, in order not to affect the work and daily life of surrounding residents, it can select low noise and ultra low noise cooling tower. Its basic working principle: when the low enthalpy contained dry air passes by the top fan, it is blown into the cooling tower from the bottom inlet screen. The high pressure high temperature water molecule in saturated vapor flows to low pressure air, wet hot water with high enthalpy dropped from cooling tower upper sprinkler system. When water-drop contacts with air, as there’s the pressure difference between vapor surface and the air, it causes evaporation under the pressure, which takes away the heat to cool down the temperature. Through analysis of its working principle, the cooling of water tower has no connection with air temperature (dry bulb temperature), but is related to wet bulb temperature in the air. The lower the wet bulb temperature, the better the cooling effect; the higher the wet bulb temperature; the worse the cooling effect. For the client who bought the Water Chiller, Shini will provide the most suitable Liang Chi Products of cooling tower for reference.

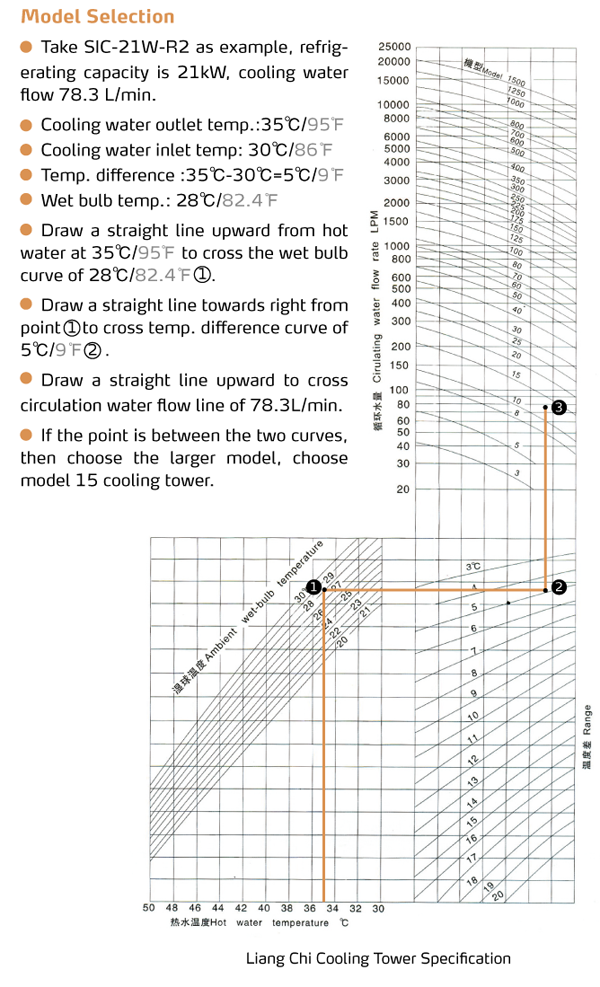

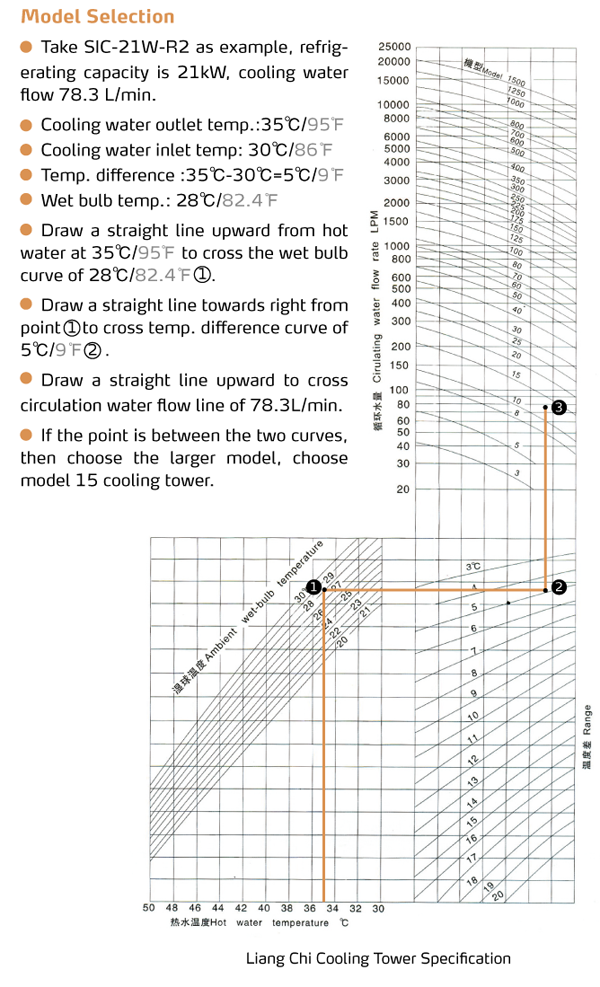

Because of the different environment (wet bulb) temperature due to regional difference, the customer also can choose the specific model according to below attached selection example as requirement. If you adopting other brand cooling tower, it can also refer the machine model to choose the water tower with similar specification. If there’s the accident caused by improper selection with less capacity, we shall not be liable for the responsibility. As to avoid the accident caused by cooling tower insufficient capacity, please use and install the machine under Shini professional technical supports.

In actual use, the cooler sometimes turns out lacking of enough heat-dissipation as the inappropriate heat-dissipation capacity of cooling tower adopted by Water Chiller, resulting abnormal operation of the machine. The risk of incorrect selection of cooling tower lies in when the Water Chiller load exceeds cooling tower heat-dissipation capacity, the water heat in tower can’t spread to ambient environment which makes cooling water temperature risen. It can’t meet the temperature requirement of inlet water, and can’t achieve condenser required rated heat exchange, synchronously the refrigerant system lasts high pressure high temperature as well. If things continue this way, the high temperature would melt the condenser components, taking refrigerant leaking method to release the pressure and reduce the temperature, it results Water Chiller suspension involving poor cooling effect of the injection molding machine which would cause dangerous safety risks, therefore the correct selection of cooling tower is crucial.

It’s forbidden to equip the water pool in cooling tower’s circulation system. As the added water pool, only can increase the amount of cooling water for water storage and buffer use, it has no heat exchange and temperature cooling functions. Moreover, as the large capacity of water pool, we don’t change the water usually. The concentration of calcium ion and silicon ion in the water pool slowly increases as use goes by. The refrigerant temperature at cooler inlet can reach 80~90℃/176℉~194℉, the water is boiling at this site, so it generates white hard incrustation like calcium carbonate and silica acid accumulated inside condenser copper pipe. The water scale is very tough insulation material which blocks heat conduction and largely affects the heat exchange of the cooler, resulting refrigerant heat can’t be taken away by the cooling water, and brings about high pressure of the Water Chiller. When this situation appears, it must use steel brush to remove the water scale on the copper pipe, or use acidic substance to melt the incrustation. As the same reason, if injection molding machine uses water pool to dissipate heat, the mould of injection molding machine is much higher than Water Chiller, the heat-dissipation tunnel inside mould will generate thicker hard scale, which results mould long last high temperature with longer de-mould cycle. The most effective method to avoid circulation water system scaling is to soften the water quality for scale cleaning. Change the circulation water once a week is available to lower the water scale possibility, and do clean the cooling tower regularly. The cooling of condenser, for Water-cooled Water Chiller, is completed by tower circulation, and the self-added water pool could turn out to be the poor effectiveness, with many troubles. Therefore, it only needs to consider the capacity of water tower in the circulation, the adding of water pool is forbidden.

In cooling water pipe engineering, in order not to affect the work and daily life of surrounding residents, it can select low noise and ultra low noise cooling tower. Its basic working principle: when the low enthalpy contained dry air passes by the top fan, it is blown into the cooling tower from the bottom inlet screen. The high pressure high temperature water molecule in saturated vapor flows to low pressure air, wet hot water with high enthalpy dropped from cooling tower upper sprinkler system. When water-drop contacts with air, as there’s the pressure difference between vapor surface and the air, it causes evaporation under the pressure, which takes away the heat to cool down the temperature. Through analysis of its working principle, the cooling of water tower has no connection with air temperature (dry bulb temperature), but is related to wet bulb temperature in the air. The lower the wet bulb temperature, the better the cooling effect; the higher the wet bulb temperature; the worse the cooling effect. For the client who bought the Water Chiller, Shini will provide the most suitable Liang Chi Products of cooling tower for reference.

Because of the different environment (wet bulb) temperature due to regional difference, the customer also can choose the specific model according to below attached selection example as requirement. If you adopting other brand cooling tower, it can also refer the machine model to choose the water tower with similar specification. If there’s the accident caused by improper selection with less capacity, we shall not be liable for the responsibility. As to avoid the accident caused by cooling tower insufficient capacity, please use and install the machine under Shini professional technical supports.

Special Reports

- Make Your Imagination Thousands of Surprises

- Review 2015 and Look Forward to 2016

- Energy Saving Technology Applied in Water Chiller

- Rotary Valve

- "The Classroom" Debuted A Huge Success

If you want to read other articles, back to2016 Quarter 2 Issue 27.