Special Reports

Rotary Valve

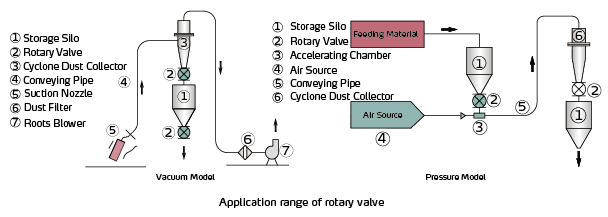

The rotary valve is designed to feed powder materials and is the most precision feeding machine. Especially, it will get optimum efficiency in pneumatic conveying system or differential pressure conditions. The materials include various plastics, food (wheat, wheat flour, granulated sugar, etc.), and minerals (coal, cement, etc.).

Shinchen is devoting herself to create higher pressure tightness seal, satisfying higher demands, providing better quality.

Main Features of Rotary Valve

Main Material

•Casing: SCS13 (stainless cast steel)

•Rotor: SCS13

•Side cover: SCS13

•Shaft sleeve: SUS304

Structure

•Material bite-proof: in order to avoid material broken, casing inlet is designed to be W shape

•Shaft seal: adopts double-lip seal ring (material: PTFE of wear resistance) which in excellent sealing performance, and don’t need daily check.

Low-pressure Rotary Valve

•Seal pressure may reach to 0.1Mpa

•Powder selects SRF type, granules select SRV type. The SRV type’s material inlet is designed to be W type to avoid material broken which is caused by material bite. Supposing the bit rate was 100% when the casing inlet is perpendicular to rotor blades, it can reduce to 50% if the rotor is in the V shape. With the W type inlet, it can reduce bit rate to 1/3 when rotor is in V shape. In addition, W type can ensure that the opening area of the material inlet is enlarged to reduce air leakage.

•The shaft seal adopts double-lip seal ring (material: PTFE of wear resistance) which brings good sealing performance, long service life.

•The upper and lower flanges of this valve are round flanges which conform to the pipe specification. The specification of flange may be selected from ANSI 150LB, DIN PN10, GB PN10, JIS 10K. However, the outer diameter and thickness of the flange follow our standard.

High-pressure Rotary Valve

•Maximum pressure difference is 0.4MPA.

•As it is in side seal structure,which largely lowers the leakage. As the side seal is soft sealing material which has wear resistance, excellent sealing performance to longer the service life.

•In order to lower the leakage of high pressure difference, there’s the exhaust pipe design on the body which can discharge the granules stably.

•Powder selects HRF type, granules select HRV type. The HRV type’s material inlet is designed to be W type to avoid material broken which is caused by material bite. Supposing the bit rate was 100% when the casing inlet is perpendicular to rotor blades, it can reduce to 50% if the rotor is in the V shape. With the W type inlet, it can reduce bit rate to 1/3 when rotor is in V shape. In addition, it can ensure that the opening area of the material inlet is enlarged to reduce air leakage.

•According to working condition, the valve bottom requires regular maintenance since its first operation.

•The shaft seal adopts double-lip seal ring (material: PTFE of wear resistance) which in excellent sealing performance to longer the service life.

•The upper and lower flanges of this valve are round flanges which conform to the pipe specification. The specification of flange may be selected from ANSI 150LB, DIN PN10, GB PN10, JIS 10K. However, the outer diameter and thickness of the flange follow our standard.

Vertical Rotary Discharge Valve LRV40 (Movable)

•Vertical rotary discharge valve is a quantitative feeder in optimal design which can receive material (granule & powder) from the container directly then convey the material to storage tank by compressed air.

•The rotary shaft of vertical rotary discharge valve is in vertical direction. It has the design of receiving material from upper cover and discharging material from middle part of the casing. Upper cover connected with air conveying pipe which can convey the air from middle part of the casing. In previous circumstance, the rotary shaft is in horizontal direction which needs accelerating chamber and has long distance between flange two interfaces. In through-type circumstance, its structure is that the lower part of the casing connected with air conveying pipe and has long distance between flange two interfaces. Vertical rotary discharge valve has short distance between material inlet and outlet on flange two interfaces. Material inlet and outlet are in V shape which can lower the material broken caused by granules bite. Vertical rotary discharge valve is movable and equipped with standard casters.

•The V shape designed casing inlet and outlet. Supposing the bit rate was 100% when the casing inlet is perpendicular to rotor blades, it can reduce 50% if the rotor is in the shape of double screw. In V tape, it can also further reduce 1/3.

Movable High Pressure Rotary Valve MHRF12

Movable high pressure rotary valve is specially designed for the container truck to unload materials, ton bags and small package from bottom part. It adopts the cross flow structure, with DC side tube connected with a delivery pipe which delivers the mixture of powder and air directly to the bunker. Side cover adopts special design which can be resistant to higher transportation pressure and adopts the design of cross flow structure to leave out the mixing chamber and reduce the height of equipment effectively. Adopting high pressure conveying mode can convey a long distance, the high mixing ratio of transmission can improve the delivery efficiency. It also can be made into a movable or fixed standard and equipped with casters.

Application of Movable Rotary Valve

•Material received from container and conveyed to storage tank by air. As it is movable, material receiving at any place is available. When machine is idle, it can be moved away and there’s no need fixed operation field.

•As distance between the outlet pipe of material storage tank and the ground is very short, generally, the rotary valve can not be replaced by other equipment.

Special Reports

- Make Your Imagination Thousands of Surprises

- Review 2015 and Look Forward to 2016

- Model Selection and Notices of Cooling Tower

- Energy Saving Technology Applied in Water Chiller

- "The Classroom" Debuted A Huge Success

If you want to read other articles, back to2016 Quarter 2 Issue 27.