-

E-Catalog

Introduction

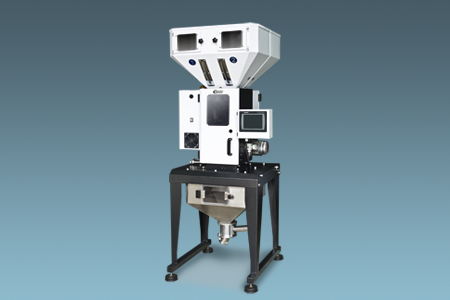

SGB series gravimetric blender can be used in the fields of injection moulding machines, blow moulding machines and extrusion lines for proportionally precise mixing of several types of material. This series machines adopt Becca levy PLC controller and latest ingredients calculation methods. The machine is controlled by an advanced microprocessor with a digital display that is simple to calibrate. The self-compensation and calibration function ensure accurate material dosing percentages. A high precision electronic weighing scale is used to ensure precise weighing of every batch and ensure accuracy to ±0.1%~0.3%. There are 8 models available to be selected based on various materials and throughputs. (This series are not suitable for powder and sheet pieces weighing)

-

Features

-

Evenly mixing of materials after accurately weighing, control accuracy strictly of ±0.1~±0.3%.

-

Auto calibration after each material weighting ensures accuracy.

-

Up to 100 recipes can be stored for later use.

-

Alarm log function.

-

All parts detachable for easy cleaning.

-

For SGB-600 and models below, machine mount model is the standard supply (equipped with magnetic base,manual discharge valve), optional pneumatic slide gate is available also.

-

For SGB-2000 and models above, floor stand is the standard supply (equipped with moveable floor stand, storage hopper and pneumatic slide gate), optional SBU suction box is available also.

-

Has the function of recycled material compensation (recycling hopper is standardly equipped with low level switch). Aberration coompensation can be automatically calculated based to the feeding amount of recycled materials.

-

Memory card can be optional selected to store ratio information for product quality control.

-

Hopper low level sensor can be optional selected to send alarm when material is insufficent.

-

Optional analog signals (0~10V) output function for screw automatic adjusting of extrusion molding machine.

-

RS485 communication is optional to realize the centralized monitoring of connecting with molding machine.

-

Floor stand, pneumatic slide gate, storage bin and suction box should be optionally purchased for floor mounting. (Applicable for SGB-600 and models below)