New Product Launch

2023 Quarter 3 Issue 51

Mini Dehumidifying Dryer MDD

With the continuous development in the plastic industry, various new materials, technologies, and processes. It raises the requests for various plastic material handling equipment, especially drying equipment. Some of these have been put changed in practical application. In occasions where the throughput of the IMM is relatively small, the miniature dehumidifying dryer can be directly mounted to the IMM has caught the market's lookout. It improves the drying efficiency and workshop space utilization and ensures the drying effect.

Typically, applications with twin tower compress air dehumidification systems (requiring high-quality compressed air) as an option to meet the demands of this application. However, some customers cannot obtain high-quality compressed air with constant temperature and low moisture content due to their limitations, which limits their options.

Shini Mini Dehumidifying Dryer MDD

Can be directly mounted at the IMM’s feed port

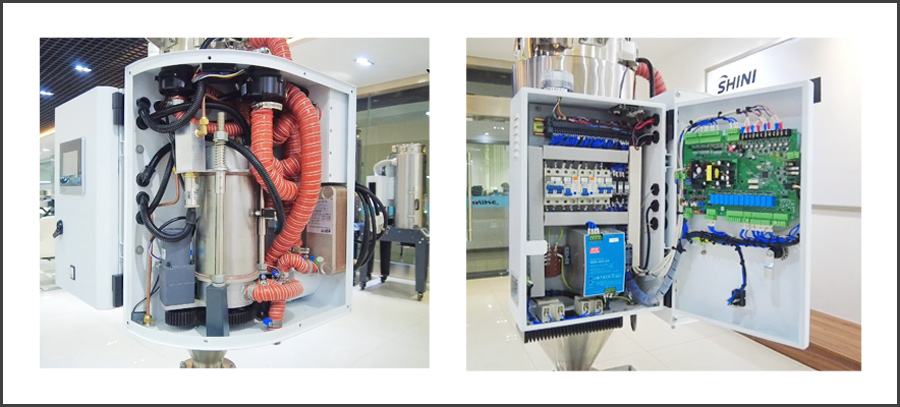

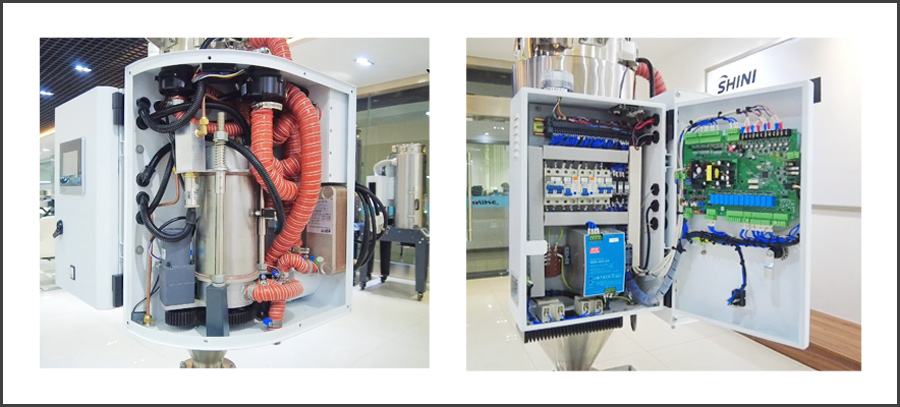

Shini has launched the mini dehumidifying dryer MDD to solve the above situations, which can be directly mounted to the IMM with market demands. This model mainly consists of the insulated drying hopper, drying process heater, regeneration heater, drying blower, regeneration blower, cooler, and desiccant wheel, and integrates the dehumidification and drying into a single unit.

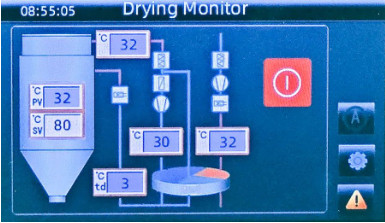

The desiccant wheel section adopts unique patented technology. It places the whole set of the desiccant wheel dehumidifying components into a tiny box, thus ensuring the dehumidifying effect and a compact structure and making a decent appearance. It uses a full molecular sieve honeycomb rotor, which can provide stable low dew point (≤-40℃) dry air under ideal conditions; Besides, it equips with a 4.3" touch panel for simple operation; microcomputer with control accuracy reaches ±1℃;RS485 interface with open protocol and standardized data architecture, providing a reliable foundation for the data interconnection; USB interface can record the data and back up the local data.

Self-adaption, auto airflow adjustment, and drying temperature

There is no logical relation between the drying heater and the drying blower for conventional plastic drying technology. In this case, if the plastic materials have been fully dried or during IMM's production interruption. The equipment continues to dry the plastics, and the blower and the drying heater are in full load; the materials will be over-drying and degraded due to the lasting high temperature, which may excessively consume more energy.

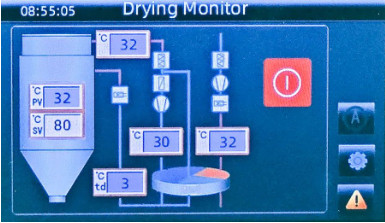

To address the above problems, the MDD collocates with the latest energy-saving intelligent drying control system by Shini. It can adjust the working status as per the return air temperature and enable the equipment to adapt and self-adjust various key parameters, airflow, and drying temperature appropriately, avoiding excessive drying and making full use of the energy.

Multiple built-in recipes

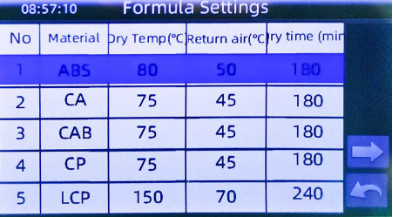

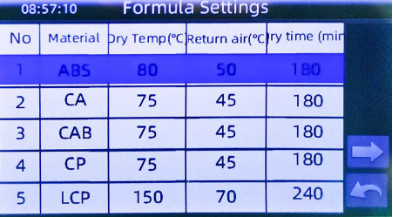

To make it easier for users to operate, the MDD controller has a built-in recipe function, and the recipe is set with 28 commonly used materials and general drying parameters. Users can directly choose materials from the recipe according to their demands for drying, thus improving work efficiency. In addition, MDD optional with a dew point monitor can unlock real-time dew point detection and dew point control functions. The dew point control function can automatically adjust the regeneration heater status according to dew point changes, reducing energy consumption.

Typically, applications with twin tower compress air dehumidification systems (requiring high-quality compressed air) as an option to meet the demands of this application. However, some customers cannot obtain high-quality compressed air with constant temperature and low moisture content due to their limitations, which limits their options.

Shini Mini Dehumidifying Dryer MDD

Can be directly mounted at the IMM’s feed port

Shini has launched the mini dehumidifying dryer MDD to solve the above situations, which can be directly mounted to the IMM with market demands. This model mainly consists of the insulated drying hopper, drying process heater, regeneration heater, drying blower, regeneration blower, cooler, and desiccant wheel, and integrates the dehumidification and drying into a single unit.

The desiccant wheel section adopts unique patented technology. It places the whole set of the desiccant wheel dehumidifying components into a tiny box, thus ensuring the dehumidifying effect and a compact structure and making a decent appearance. It uses a full molecular sieve honeycomb rotor, which can provide stable low dew point (≤-40℃) dry air under ideal conditions; Besides, it equips with a 4.3" touch panel for simple operation; microcomputer with control accuracy reaches ±1℃;RS485 interface with open protocol and standardized data architecture, providing a reliable foundation for the data interconnection; USB interface can record the data and back up the local data.

Self-adaption, auto airflow adjustment, and drying temperature

There is no logical relation between the drying heater and the drying blower for conventional plastic drying technology. In this case, if the plastic materials have been fully dried or during IMM's production interruption. The equipment continues to dry the plastics, and the blower and the drying heater are in full load; the materials will be over-drying and degraded due to the lasting high temperature, which may excessively consume more energy.

To address the above problems, the MDD collocates with the latest energy-saving intelligent drying control system by Shini. It can adjust the working status as per the return air temperature and enable the equipment to adapt and self-adjust various key parameters, airflow, and drying temperature appropriately, avoiding excessive drying and making full use of the energy.

Multiple built-in recipes

To make it easier for users to operate, the MDD controller has a built-in recipe function, and the recipe is set with 28 commonly used materials and general drying parameters. Users can directly choose materials from the recipe according to their demands for drying, thus improving work efficiency. In addition, MDD optional with a dew point monitor can unlock real-time dew point detection and dew point control functions. The dew point control function can automatically adjust the regeneration heater status according to dew point changes, reducing energy consumption.