Special Reports

New Brand Image Shines at CHINAPLAS 2013

Overview:

Date: May 20th- 23rd, 2013

Venue:

Theme: The Future is in Plastics and Rubber

Exhibits: Equipments for plastic and rubber,

processing equipments for rubber and quality detecting instruments, plastic

products plus plastic films, industrial chemicals for rubber processing,

auxiliary materials, molds and accessories for rubber processing, rubber and

plastic products.

Introduction: CHINAPLAS has been admitted one

of the most influential plastic exhibitions in this filed. It has a long

history since the opening year 1983 and till now it has been held for 27 times

successfully. To date, CHINAPLAS has grown into Asia’s first and world’s second

international plastic and rubber industrial exhibition, to provide

opportunities of information exchanging for all plastic relevant fields

globally and a platform enterprises and corporations striving to expand or

consolidate

New Product

Launch

Before the exhibition, on May 19th, the technology marketing department of Shini group held a new product releasing conference, giving all the agents domestically and overseas a fully understanding of the new products which would appear in the show. The conference was a success with about 50 agents and distributors’ participation. They were informed the new products and products developed and knew definitely how to promote them to the customers.

The conference was organized and held by our

marketing department and all presentations were edited and prepared by our

senior technical engineer in which strong points had been highlighted and lots

of videos and dynamic demonstrations had been given. The conference was highly

approved and praised by the attendees.

Sharing

Activities held simultaneously each year was

also a focus in the industry. After the future zone and future automobile

showed lasted year, construction industry has been one key focus for CHINAPLAS

2013. China has the world’s largest market for construction industry with 2

billion square meter floor areas added each year, among which over 80% are high

energy consumption constructions. Therefore, the energy conservation and

emission reduction in building industry is more and more important. This time,

the exhibitions gathered powerful line-ups from domestically and overseas,

setting up showcases and holding exchanging activities, from which visitors can

feel and learn the environmental-friendliness, excellent lighting and architectural

aesthetic of the plastic building materials. Plastics and rubber were surely to

continue to shine in construction fields.

In addition, on May 19, one day before the

official start of CHINAPLAS 2013, a conference to discuss “International Quality

Partnership and Social Responsibility in Plastics Processing” was held, with a

twin focus on quality OEM partnership as well as responsible and

environmentally friendly packaging for industrial, consumer goods and food

applications. The OEM development forum was focused on consumer electronics and

home appliances with the topic of how to provide useful solutions for OEM

partnership by creative materials and processing techniques. And the

environmental packaging forum was focused on how to select and make use of

advanced packaging material to enhance convenience and safety and in succession

greatly decrease environmental load and efficiently implement social

responsibility.

Spotlight

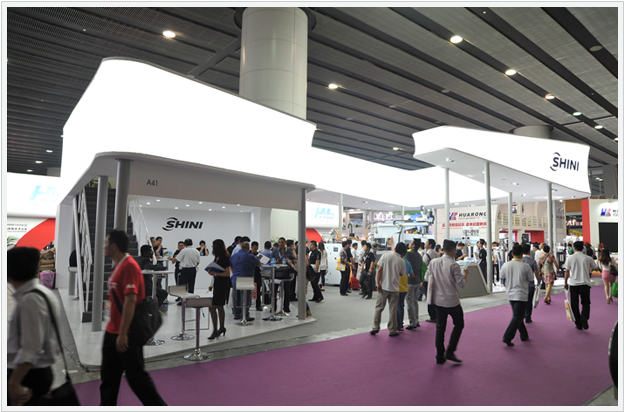

New Look, A Different Shini

Shini group chose this exhibition as the best

time to release its fire-new brand image to the visitor from all around the

world. Highlighted in its brand value of “Simple Solution”, together with

technical rationality and precise, Shini presented its high-end positioning of

products and its industrial characteristics. On the site, from the style of

booth construction to the image of the staff, from the appearances of the

products to the modification of deeper functional design and operation methods,

the core brand value “Simple Solution” was always there, easily shown and feel.

This time, Shini brought not simply visual impact, but also one expectation for

the future, to leap forward and self-transcend.

Precision and Automation

With the releasing of new brand image, Shini

also brought its latest products from which we can see the powerful R & D

capacity. Gravimetric doser SGB, Loss-in-weight feeder SLWF, a full system of

automation picking and packing equipments, as well as side entry robot SSE are

all presented at the show which all spoke volumes for the advanced technology

Shini had achieved in precision and automation.

Full-automatic Picking and Packing System

Solution

Usually, labor amount is a huge in plastic

products processing. In a time that labor cost is always increasing, how to

efficiently save labor cost and make full use of current equipments is an

important problem confronting the manufacturers. Full-automatic solutions are

inevitable because they can greatly reduce the number of workers in the

products processing and in success reduce labor cost. This time, Shini strongly

launched its full set of automatic picking and packing system. This system is

three axes servo driven robot collocated with osculum fixture to pick out and

place the products on special equipments, then with the help of pneumatic arm,

the products enter into the packing machine to be packed and then be sent out

through conveyor.

Application of Precise Gravimetric Dosing

Technology

Gravimetric doser showed this time combine

material feeding and loss-in-weight metering into one single unit. Adopt

advance loss-in-weight metering technology, the feeding process can be

monitored and together with the optimized feeding screw assembly, SGD series doser

can meet very high precision requirements. This series are mainly applied in

precise dosing of masterbatch and additives, especially in applications of

micrometric dosing, they are highly stable. In addition, SGD series dosers can

automatically monitor the dosing situation of mastetbatch or additives; also it

can be connected to controller through Ethernet and features data save function

which is free from power failure.

Application Starve Feeding Technology

SLWF series feeders adopt loss-in-weight metering

device together with vertical screw to feed, PLC and transducer to control and

real-time detection of dosing to fill the molding screw incompletely, thus to

achieve starve feeding. Several feeders can be combined to achieve accurate

dosing of multiple materials.

New Tech in Automation

A brand new robot was promoted at the show.

SSE-1600 side entry robot, with traverse stroke of

Extrusion Control Technology

The joint venture company Shini-Syncro showed

its eaSYroto+ eaSYmex oscillating ring plus gauging system, SYline-S-Master

loss in weight hopper and eaSYbatch-S-4 gain in weight batch blender.

eaSYroto+eaSYmex oscillating ring plus gauging

system is a circular thickness measuring control system for bubble with fold

diameter less than

SYline-S-Master loss in weight hopper is mainly

made up of two parts, vacuum hopper and loss in weight hopper. It is suitable

for extrusion control applications of pipe, sheet or film with maximum

throughput of

eaSYbatch-S-Master series blender is suitable

for gravimetric dosing of multi-component materials in extrusion control

processing. By controlling the speed of extrusion screw and pull roll, a

constant throughput and gram/meter can be achieved with maximum throughput of

Special Reports

- Starve Feeding

- The Principle and Application of Industrial Air Chiller

- Cold Mold Sweat Dehumidifier

- Temperature Control in Hot Runner System——Heaters

- About CHINAPLAS 2013 of Shini-Syncro Extrusion

If you want to read other articles, back to2013 Quarter 3 Issue 16.