Special Reports

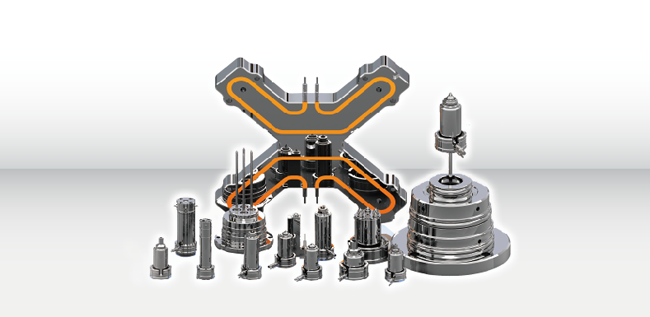

In What Circumstance to Use Hot-runner

Economy

From the economic point of view, whether it is to use the hot-runner system or not, is usually determined by comparison between the input costs and return profits of adopting the system. In actual consideration, it should rely on the calculation and comparison according to the details of production circumstance.

Suppose within the total production cycle of a year, if the amount of cost saving and energy saving by using hot-runner system plus the total amount of improved production efficiency and amplified production scale brought additional profits are two times more than the costs of hot-runner system, it means there’s no risk for the injection molding manufacturer to invest the hot-runner system.

Technology

From the technological point of view, whether it is to use the hot-runner system or not, is ordinarily determined both by product’s R&D team and mould manufacturer. During the judging process, it can invite the hot-runner supplier to take part in the discussion and to provide necessary technological supports.

In normal circumstance, for some large, thin plastic injection products or products with complicated structure, such as large television shell, automobile bumper, air conditioner cover, when it is hard and difficult in molding by using of cold-runner, the hot-runner will be the first replacement of technique means.

Though some plastic injection products can be in molding smoothly by using cold-runner, the property requirements of the products, such as mechanic characteristic, cosmetic, optical requirement, shape and stable structure, usually need hot-runner system to improve their plastic mobility. Especially if it uses needle valve hot-runner system, via effective time control, it can change the melting trace distribution and even eliminate the melting trace.

Special Reports

- Industrial Water Chiller COP Introduction & the China Standard

- The PET Crystallizer SCR Improvement

- RS485 Communication Interface Applied in Mould Temperature Controller

- Working Principle and Practical Implication of Cyclone Separator

- Conveying Control Differences between SHR-U-(E) S Applied on SGB and Other Machine

- Application of SICH-U Insulated Collective Hopper

- About Shini Europe

If you want to read other articles, back to2015 Quarter 2 Issue 23.